September 13, 2017 Rotochopper, Inc. hosted their 7th annual Demo Day. Approximately 120 customers and prospects from the US and Canada attended the event with the theme “See Red Go Green”.

The day began with tours of the state-of-the-art manufacturing facility, providing attendees the opportunity to see Rotochopper grinders in every stage of manufacture, from cutting to final inspection and testing. The facility tours also provided guests the opportunity to meet the teams who design, build, and support their Rotochopper equipment.

President/CEO Art de St. Aubin welcomed attendees with remarks focused on the partnership Rotochopper forms with its customers and discussing the initiatives the company is undertaking to further support those partnerships saying, “It is our honor and privilege to partner with you. Our long-term partnerships with customers are driven by Rotochopper’s core values: loyalty, commitment, service, pride and community. We will continue to position ourselves to help your businesses succeed and differentiate ourselves from our competitors.”

The demonstrations started with the unveiling of Rotochopper’s prototype heavy duty B-66 track and dolly unit, with a 1050hp engine and upgraded infeed features enabling it to devour logs and whole trees. The 765 and 950 hp B-66, FP-66, MC-266 and MP-2 demonstrated converting raw materials into finished products throughout the day for attendees. Mini sessions demonstrated the new corn grinding option for the CP-118, silt sock attachment for the GB-250, and Rotochopper’s patented screen installation system and replaceable mount rotor.

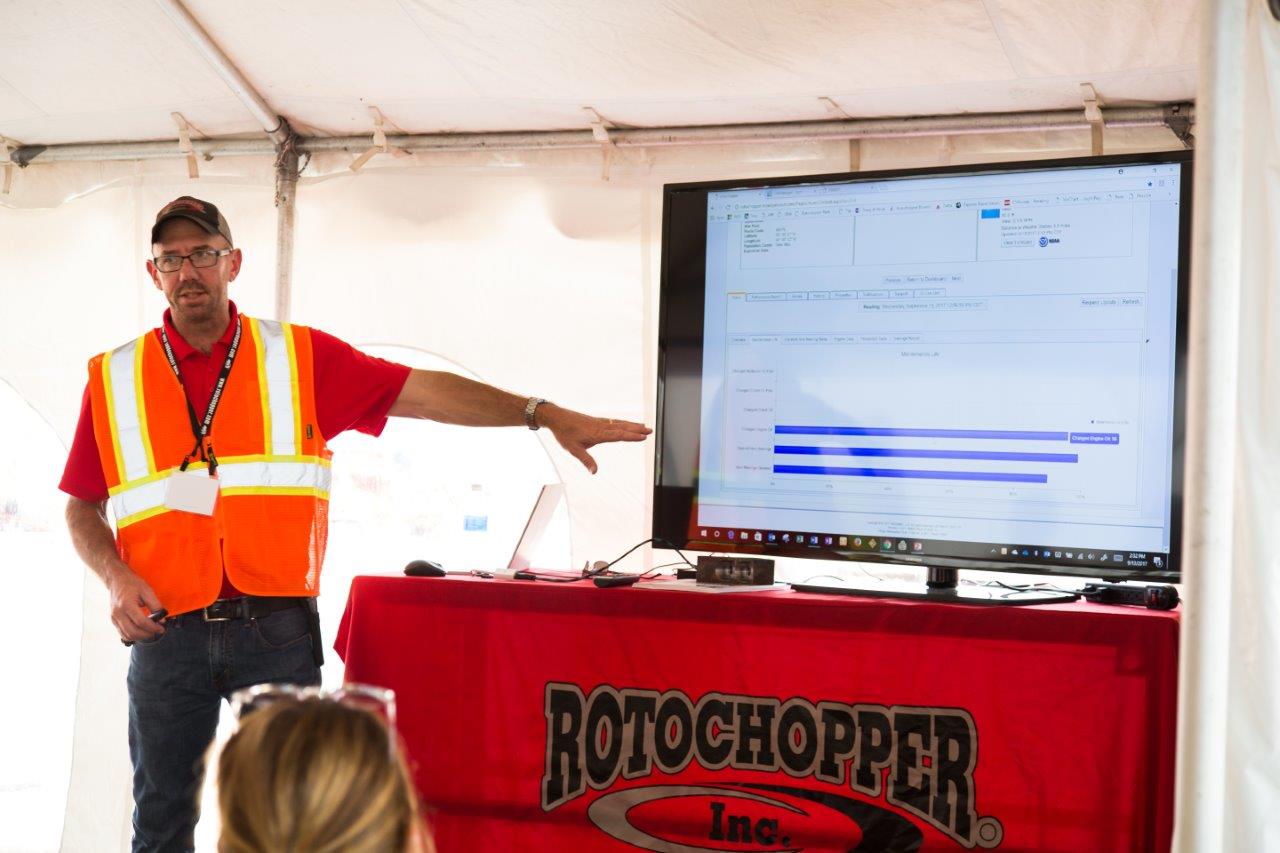

Rotochopper customer service unveiled the new RotoLink® system which allows customers to connect with their machines and Rotochopper customer service to troubleshoot and track machine performance in real-time. The newly redesigned 24 tooth replaceable mount rotor with increased impact resistance and reduced side load during operation was on display. The day ended with a side by side demonstration of a B-66 and an FP-66 equipped with Rotochopper’s Generation 2 Colorizer providing “Perfect in One Pass” coverage, while minimizing inputs like colorant and water usage.