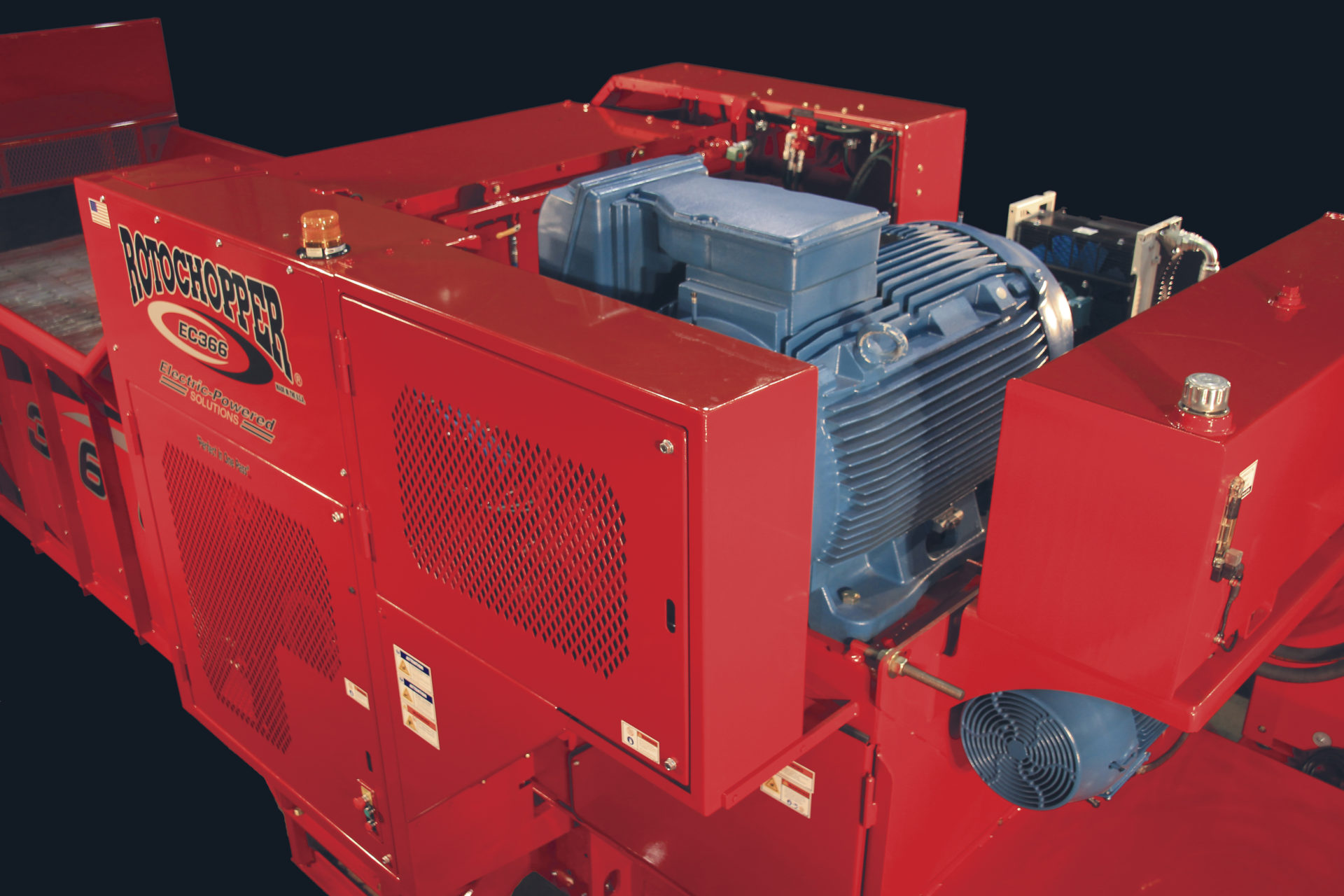

The advantages of electric-powered equipment over diesel models extend well beyond the obvious savings on diesel fuel. Electric-powered grinding equipment can significantly reduce operating and maintenance costs, while providing unbeatable dependability and uptime. To further optimize the natural benefits of electric equipment we offer the most extensive line of electric grinders on the market, each designed with the same commitment to particle size control and versatility as our diesel models. With Rotochopper electric-power equipment, you can slash your operating costs without sacrificing the flexibility or capacity of your operation. With the widest range of size and horsepower on the market, we offer electric-powered grinders to meet the needs of diverse operations with optimal efficiency.

Cost-Saving Benefits

Besides savings on diesel fuel, electric powered equipment eliminates the costs and downtime associated with maintaining a diesel engine, radiator, and clutch (or other power transfer system), including:

- Oil & filter replacement

- Coolant exchange

- Air filter replacement

- Clutch fluid & filter replacement (where applicable)

Long-Term Benefits

In addition to reduced routine maintenance and downtime, electric grinders offer considerable savings on long-term maintenance and operation expense. Rotochopper electric grinder owners frequently log thousands of hours of operation with no need for major maintenance. The increased uptime of Rotochopper electric-power grinders makes them particularly popular with C & D recyclers, pallet recyclers, biomass plants, and other operations with steady flows of raw material to process under strict specifications.

Want to see how much you can save by switching to electric? We would be happy to provide operating cost projections for your operation. Give us a call or contact your regional sales representative to learn more about the cost saving benefits of Rotochopper electric grinding solutions.