Efficiency and productivity are vital in the world of waste reduction—especially in the wood waste recycling market. To optimize your horizontal grinder’s performance and your operation overall, incorporating supporting equipment from a trusted manufacturer is key.

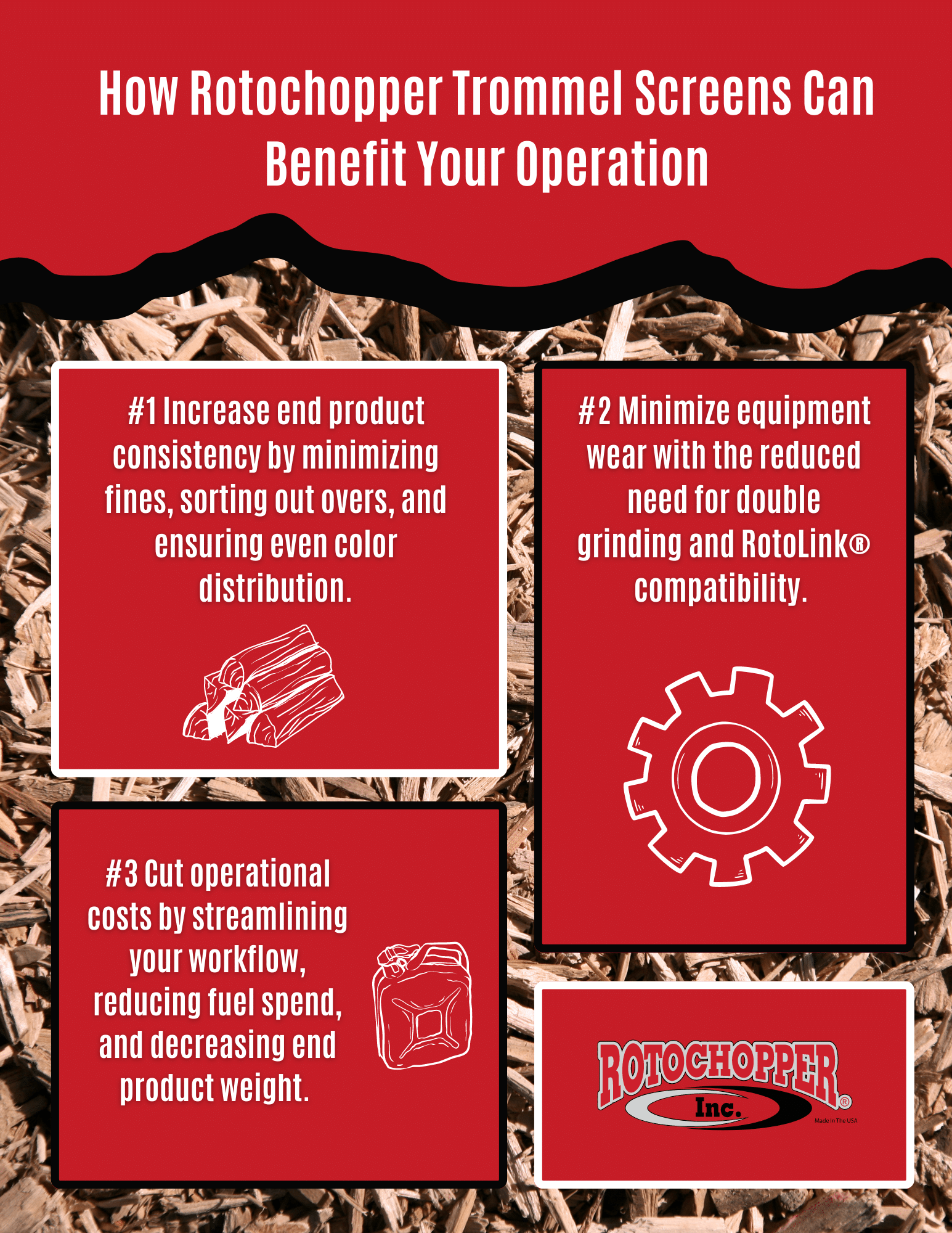

Let’s delve into three significant benefits your grinder can reap from a supporting trommel screen.

#1: Increase End Product Consistency

Integrating a trommel screen into your horizontal grinding operation presents a significant advantage by reducing the need for double grinding. Double grinding occurs when irregularly sized material passes through the grinder multiple times. This results in inconsistent material sizes, something that can be problematic for operations trying to meet the demanding size specifications of their industry.

By incorporating a trommel screen, operators can bypass this issue and achieve more consistent, uniform final end product sizes. The trommel screen acts as a highly effective size separator, sorting out overs that may require a second pass from similarly sized material that is ready for the next stage of processing or bagging.

This saves your operation time and ensures only oversized material needs to pass through the grinder again. The result is a more streamlined and efficient workflow that minimizes double grinding.

Minimize Fines

Rotochopper’s trommel screens can help minimize the inclusion of fine materials in your end product. The screen’s rotating drum effectively separates the ground material based on size. The sorted fines can be discarded or sold as a secondary product for use in compost, wood flour, or wood pulp production.

Consistent Color

Like Rotochopper’s patented horizontal grinder screen change system, changing the screen on your trommel is quick and easy. For operators looking to produce high-quality colored landscaping mulch or playground chips with the MT 175, the screen can be swapped with a solid drum and paired with our colorizer system. The drum angle can also be hydraulically adjusted to ensure consistent color throughout your end product.

Adding a trommel screen to your horizontal grinding operation ultimately improves the overall quality of your end product and enhances the efficiency of your wood waste recycling operation.

#2: Minimize Equipment Wear and Tear

The trommel screen reduces the amount of wood waste that requires a second grind, which, in turn, minimizes the strain on your horizontal grinder’s components, including teeth, screens, and bearings. As a result, operators can reduce maintenance costs and downtime associated with frequent wear part replacements.

Rotochopper MT trommel screens are also completely compatible with our supporting technology, RotoLink®, which can help reduce wear on your trommel screen itself. The RotoLink remote monitoring system allows operators to access real-time telematics—any time from anywhere. With access to information on wear part lifespan, maintenance needs, and machine health, you can count on increased uptime, improved reliability, and a longer operational life for your equipment.

#3: Reduce Operational Costs

Incorporating supporting equipment like a trommel screen into your grinding business improves operational efficiency and offers significant cost-saving benefits. One of the primary cost-saving factors is the reduction in processing time.

The trommel screen effectively separates the desire-sized end product early, allowing some material to bypass the grinder and proceed directly to the next stage. This streamlined material flow minimizes the need for multiple passes and translates into substantial time savings, enabling you to process more material in less time and increase overall productivity.

Eliminate Inefficiencies

As previously mentioned, Rotochopper’s trommel screens are compatible with RotoLink. Along with maintenance needs, RotoLink can monitor production rates, uptime, and machine performance, allowing operators to spot and easily correct inefficiencies in their workflow.

The hydraulically foldable conveyors on the MT series trommel screens can also help reduce unnecessary material handling, further minimizing your operation’s labor or equipment costs.

Lower Fuel Costs

Using a trommel screen can lead to lower fuel consumption. By reducing the amount of unnecessary grinding, you optimize fuel efficiency and minimize energy waste. This lowers operational costs and contributes to a more sustainable and environmentally friendly operation.

Fines Reduction

The trommel screen’s reduction of fines lowers the weight of your end product, making it more cost-effective to bag and transport. If your operation is producing colored mulch, the exclusion of fines additionally reduces the amount of colorant needed, further cutting costs.

Reduced double grinding and reduced production of fine materials also result in less wear and tear on the grinder’s components, leading to decreased maintenance and replacement costs over time. These savings can positively impact your bottom line while you maintain high-quality output.

Optimize Your Grinding Operation With Rotochopper

Incorporating supporting equipment, specifically a trommel screen, into your grinder setup brings undeniable benefits to your wood waste recycling operation. If you’re interested in exploring how our MT series trommel screens can benefit your wood waste horizontal grinding operation, contact Rotochopper today.