Rotochopper, a leading manufacturer of horizontal grinders, shredders, and screening equipment, successfully wrapped up its annual Rotochopper University training program […]

Learn MoreGB-250

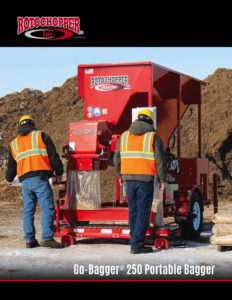

Retail Bagging Machine

Fill It. Seal It. Sell It.

The Rotochopper Go-Bagger® 250 can fill and seal bags filled with landscape mulch, decorative rock, sand, compost, topsoil, and many other commodities commonly offered in retail bags.

Contact a Sales Rep

Featured Specifications

Nothing makes it easier to get your bulk commodities in front of consumers in retail bags than a Rotochopper portable bagging system.

-

Advantages

Bagging Simplified

The Go-Bagger® 250 allows you to diversify into the retail bag market without the complexity and cost of a larger automatic bagging system.

Rugged & Versatile

If you’ve seen it in retail bags, the Go-Bagger® 250 can handle it, thanks to heavy duty construction and a user-friendly design.

Compact & Quick

The Go-Bagger® can be towed with a pickup truck and sets up in just minutes to fill and seal bags anywhere you produce bulk commodities.

Hands Free Sealer

Easily adjust the sealer to match unique variables such as bag thickness and ambient temperature and effortlessly seal with a tap of the foot pedal.

Roller Bed Bag Conveyor

The Go-Bagger® is equipped with a roller bed allowing operators to quickly and easily move bags through the fill and seal process, increasing efficiency.

Digital Controller

The controller lets the operator quickly and easily fine tune and save settings by volume or by weight to ensure evenly filled bags.

-

Exclusive Features

Hopper with Agitator

A slow-speed agitator breaks apart compacted material to maintain even filling and uptime.

Interchangeable Bagging Jaws

Easily change bag filling jaws to match bag sizes – ranging from 2 cubic foot mulch bags to flood retention sand bags.

Erosion Sock Attachment

This optional attachment allows you to diversify your operation even more, maximizing the value of your resources.

-

Videos

Rotochopper GB-250 Erosion Sock Attachment Demo Day 2018

Watch the Rotochopper Go-Bagger® 250 with erosion sock attachment fill erosion sock with coarse fiber at Demo Day 2018.

Subscribe to our YouTube ChannelAdditional Videos

- Compost Grinding Solutions

- Demo Day 2019 Recap

- Rotochopper: Waste Grinding Solutions

- Customer Testimonial: Mark LeBrun – Mid Minnesota Grinding & Mulch

- Rotochopper: Demo Day 2017 Recap

- Go-Bagger 250: Erosion Sock Demo (Demo Day 2017)

- Rotochopper: Colored Mulch Solutions

- Bagging mulch with the Rotochopper Go-Bagger 250

- Industries

-

Additional Specs

Dimensions

- Length: 15′ 8″

- Width: 6′ 10″

- Height: 8′ 7″

- Weight: 4,500 lbs.

Power Supply

- 20 HP diesel engine

- On-board generator

- Hydraulic displacement pump

- Optional electric configuration

Hopper

- 2.5 cubic yard Hopper

- Variable speed feed belt

- Removable full length hopper agitator with variable speed hydraulic drive

- Removable hopper side

The Go-Bagger® 250 is also available as an electric model.

To learn more about this option – contact your sales representative.

Erosion Sock Filling Attachment

With the addition of the erosion sock attachment you can diversify your grinding and bagging operation even more, maximizing the value of your resources and providing additional distribution opportunities. Efficiently switch from filling bags to filling erosion socks in less than 20 minutes.

- Fill erosion sock with compost or ground wood for erosion and sediment control

- Accommodates 9″ and 12″ standard erosion socks (larger custom sizes available as needed)

Additional Resources

5 Ways to Limit Equipment Repair Costs

In the world of horizontal grinding, downtime is money lost. Ensuring your machines are operating at peak efficiency is a […]

Learn MoreHow Rotochopper Serves the Whole Orchard Recycling Industry

Whole Orchard Recycling (WOR) plays a critical role in sustainable agriculture by transforming retired orchards into valuable soil nutrients or […]

Learn More